Urbana, Ill. – A team from the University of Illinois Urbana-Champaign’s Grainger College of Engineering and Mayo Clinic have developed a new technique for creating “microcancer” cell cultures. It allows researchers to form hundreds of microcancers in a high-throughput format using a small, microfabricated chip, enabling direct measurement of cell health or response to drugs. It also allows researchers to control the shape of the culture using capillary forces and thus create cultures that more closely resemble in-vivo cells’ three-dimensional geometry.

The work was recently published in Science Advances. It was completed as part of the Mayo Clinic and Illinois Alliance for Technology-Based Healthcare.

A cancerous tumor’s microenvironment – the area where cancerous cells interact with healthy tissue through physical contact or by exchanging extracellular signals back and forth – has significant influence on how a tumor progresses and responds to cancer-fighting medications. Reproducing those cells in a culture that can be imaged and studied is a crucial step in cancer treatment. Ideally, that culture takes a very small sample of a patient’s tumor and produces an array of hundreds to thousands of tiny, uniform tumors – microcancers only a few hundred micrometers in diameter.

“The tumors in these cell cultures have to match when compared to the source tissue,” said Anurup Ganguli, who is the first author on the study and now research scientist in the Holonyak Micro and Nanotechnology Laboratory. “The technique we have developed works even when there is very little tissue in a biopsy and would allow physicians to test many drug treatments against an individual patient’s cancer quickly and decrease the time for deciding on what therapy to use,” Ganguli was previously a graduate student in The Grainger College of Engineering’s Department of Bioengineering.

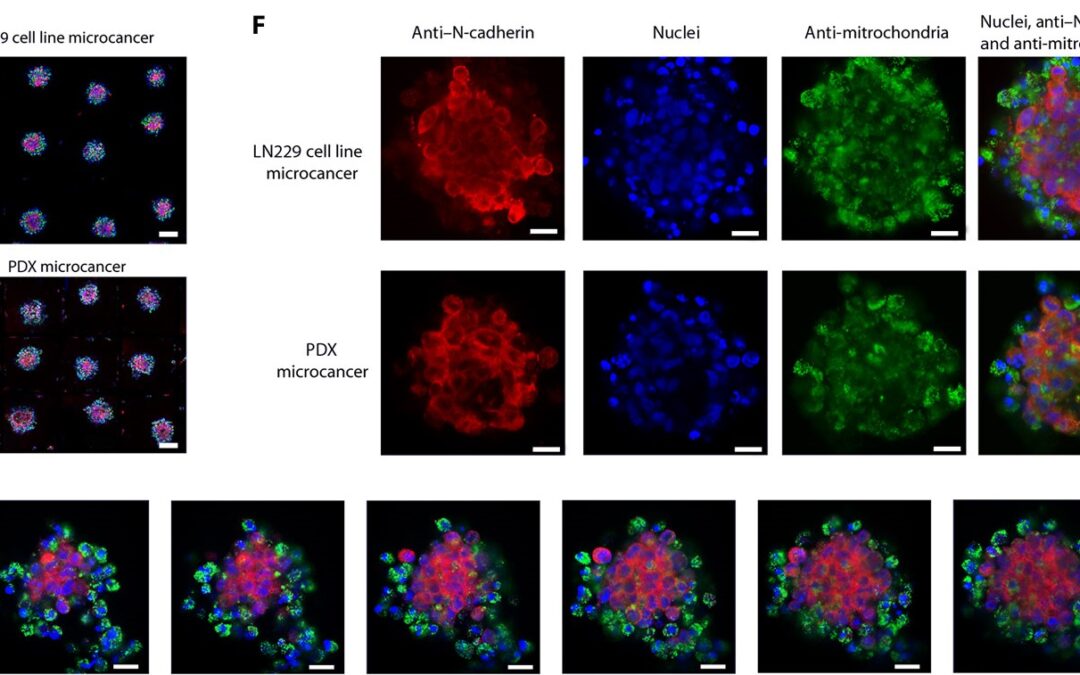

In the Science Advances study, the team fabricated microchips with circular, square, and triangular wells etched into them. The chips are less than the size of a quarter and can contain as many as 900 of the square microwells. Exposing the chip to oxygen plasma makes the surface hydrophilic and spinning it in a centrifuge draws the sample of human cancer cells through the length of the well. Finally, the chip is inverted in mineral oil to create inverted hanging drops.

“Most 3D culture techniques are slow or are produced in a way that introduce unpredictable interactions that bias downstream applications of the samples, such as their use to predict how a patient’s tumor will respond to therapy. Here, however, we avoid those issues and offer a simple, scalable, and customizable platform suitable for drug screening purposes in precision medicine, as well as a broad range of applications in drug discovery, regenerative medicine, stem cell research, and biotechnology,” said Panos Anastasiadis, professor of cancer biology and member of the Precision Cancer Therapeutics program at the Mayo Clinic Center for Individualized Medicine, who co-led the study.

“The microcancer tumors that formed in the chip’s well matched closely with the team’s target sizes and were very consistent in size, shape, and molecular profile. This consistency means that the physiological function of the samples closely resemble activity in the human body. Cancer cells and their microenvironment exchange physical, chemical, and mechanical cues as they would in vivo,” said Rashid Bashir, dean of The Grainger College of Engineering and Professor of Bioengineering and in the Holonyak Micro and Nanotechnology laboratory, who also co-led the study.

Others senior authors included Professor Andrew Smith from UIUC’s Department of Bioengineering, and Drs. George Vasmatzis and Farhad Kosari from the Mayo Clinic’s Center for Individualized Medicine.

Teams at Mayo Clinic and the University of Illinois have been working closely together for more than a decade now.

“This work is just one example of the positive impact that the Mayo Clinic and Illinois Alliance for Technology-Based Healthcare has had on advancing health,” said Neal Cohen, director of the Interdisciplinary Health Science Institute at UIUC, “In just the last year we’ve developed new bioinformatics techniques, and a new platform for complex genomic analysis. These long-term, well-supported collaborations make all the difference as we strive to improve lives and expand the future of medicine.”

– Written by Bill Bell, Grainger College of Engineering